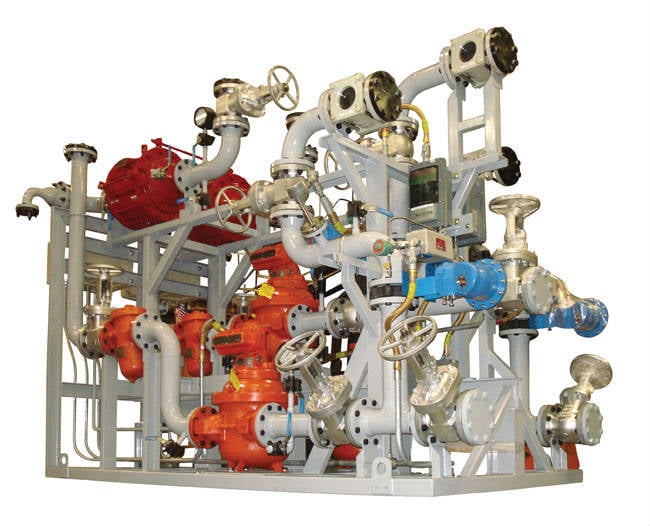

There are so many positive attributes to having a skid-mounted system. If your company deals with hazardous chemicals, a skid-mounted system can ensure safe handling with filtration, pumps, valves, grounding, accurate metering and more. With this type of system your employees are better prepared to handle dangerous liquids such as caustic, bio-diesel, and ethanol making spills less likely. It is also possible to design a user-friendly integrated loading rack system for rail cars and tank trucks.

The skids themselves are made of sturdy, hot dipped galvanized steel and can fit in a smaller footprint than separate pieces of equipment would. Because everything is all on one skid, it’s easy to install as soon as you receive it and should be up and running in just a few hours. And when you need to perform maintenance all parts are located in one place and easily accessible.

The skids themselves are made of sturdy, hot dipped galvanized steel and can fit in a smaller footprint than separate pieces of equipment would. Because everything is all on one skid, it’s easy to install as soon as you receive it and should be up and running in just a few hours. And when you need to perform maintenance all parts are located in one place and easily accessible.

Skid mounted systems can be designed to meet the specific requirements of a company’s work site. Usually the business building the system will work with you to find out exactly what is needed to make your company job tasks move more smoothly to increase throughput. Then engineers will design and construct the skid-mounted system that meets your company’s needs.

One example might be a load-out system that has custody transfer metering capabilities and six bottom loading arms. Six vertical metering systems would be set up and tested to ensure extreme accuracy. When complete, the system will be delivered ready to set up and use.

The current demand for affordable oil is at an all time high and these types of systems can aid your business by correctly metering and loading/unloading liquids. Systems are job-specific, so they should be constructed to your exact needs – not some pre-built system that requires you change your processes.

Following are a few types of integrated liquid custody transfer systems that can help companies improve processes and handle hazardous liquids more safely:

- Fluid blending, injection, and metering

- Custody transfer systems for crude oil, bio-fuels and LPG

- Loading/offloading applications for tank trucks and rail cars

- Top or bottom loading

- Multi-station loading and unloading systems integrated with the latest technology.

- Terminal truck loading and blending systems for gasoline and diesel

- Optional integration of the new system with your control system

Other benefits include:

Other benefits include:

- A compact design suited for limited space on the job site

- Reduced installation time – due to testing before shipment

- Systems built for easy access and low maintenance

- Turnkey systems with one source for responsibility

- Reduced operating costs

- Improved reliability and operating safety

The turnkey process allows a client to deal directly with one company that will design, supply and guarantee the products, avoiding possible problems between suppliers.

Having extensive knowledge of skid-mounted systems, engineers at Carbis can evaluate, design, construct and test a system that will meet the needs of your company making handling hazardous liquids safer, more efficient and creating better throughput for employees.

If you have any questions, click here to contact Carbis or call us at 1-800-948-7750 and we’ll help you determine the best bonding and grounding equipment for your company.